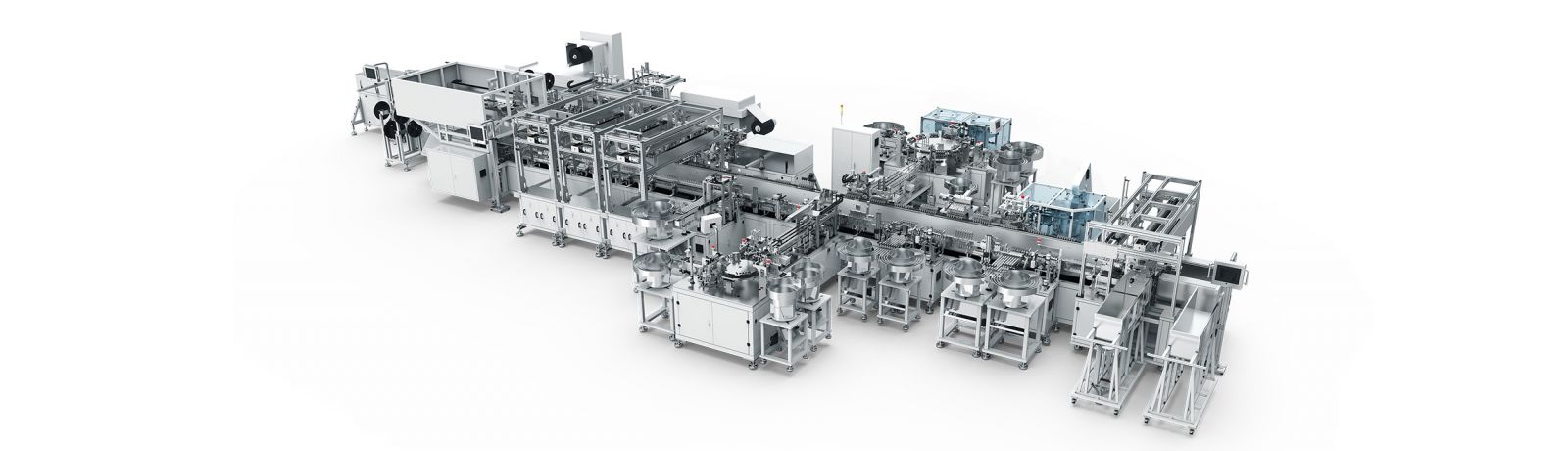

The disposable IV infusion set comprises several parts with a complicated structure. Strict requirements are imposed on the assembly process, including the accurate completion of each assembly procedure, to ensure the final products meet the relevant specifications.Maider has independently developed an automatic assembly line for disposable IV infusion set, an industry-leading intelligent manufacturing system for medical consumables. Deviating from traditional manufacturing that relies on manual assembly, this system realizes the automatic adhesion and assembly between IV tubing, roller clamp, roller, medicine filter, drip chamber, spike, and other components. This system realizes a highly-automatic assembly process, effectively overcoming the challenges of traditional manual assembly/manufacturing, high risks of contamination, and low yield rate. This, in turn, leads to significant improvement in productivity, reduction in labor intensity, and decrease in production costs. Maider, therefore, has received bulk purchase orders from numerous medical enterprises worldwide.